DIY Electronics: Building Your Own Hardware from Scratch

Demystifying the Arduino Uno: A Comprehensive Guide to its PCB, Components, and Breadboarding Essentials

This tutorial aims to provide a thorough understanding of the inner workings of the Arduino Uno, breaking down its printed circuit board (PCB) and components, and explaining how to replicate its functionality using just a few essential parts. By the end, you’ll have a clear grasp of each component’s role and which ones are crucial to the board’s operation.

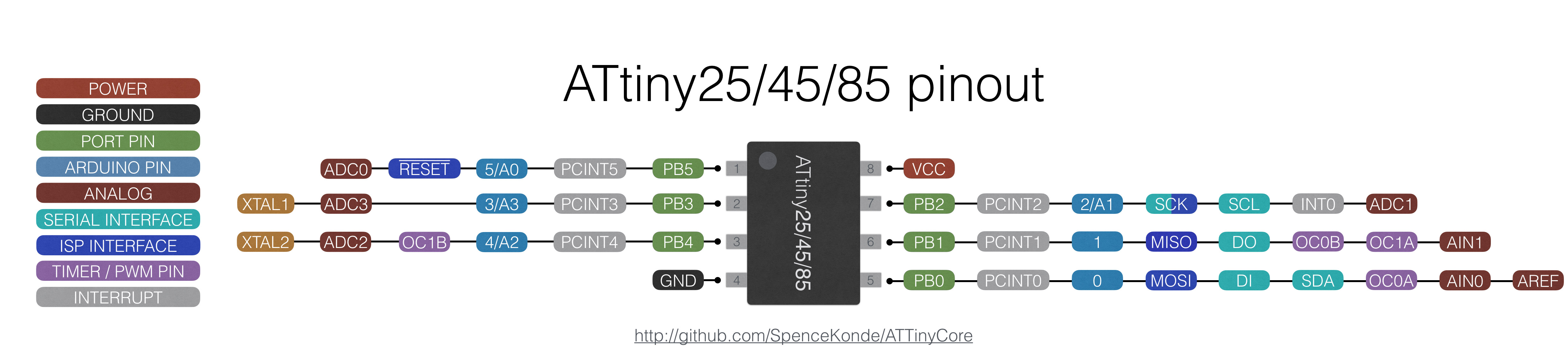

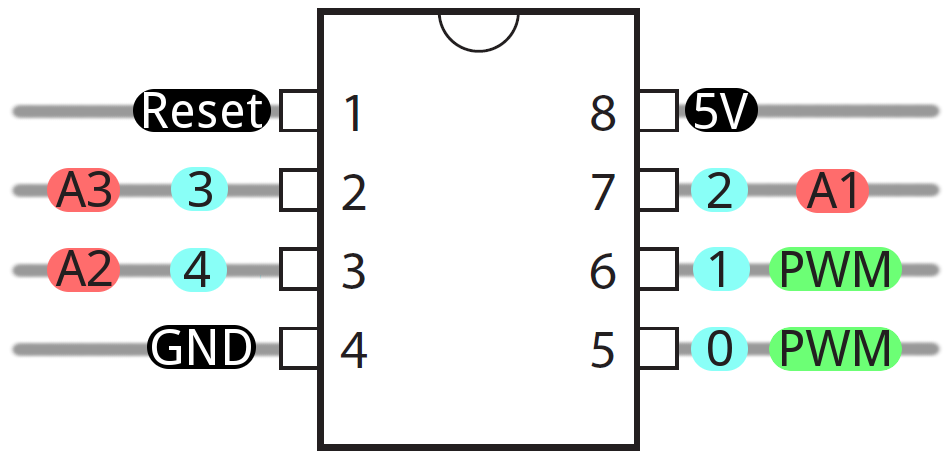

The Microcontroller

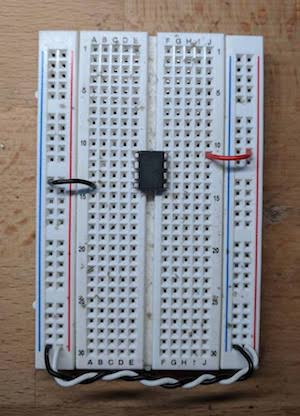

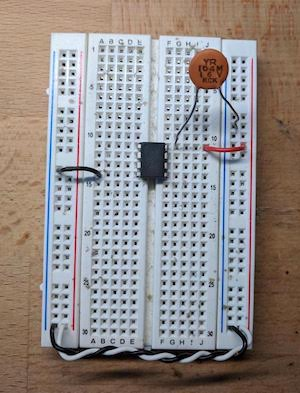

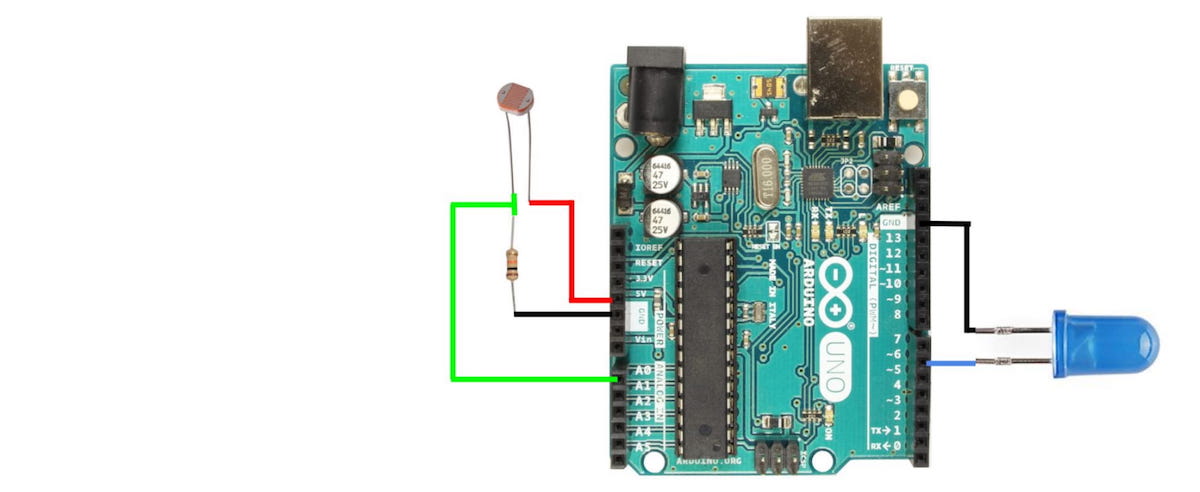

When making projects with an Arduino, we tend to think of them like the image below. We have a sensor connected, and maybe an LED, and we connect those components to the Arduino’s pins. Then, our code can be uploaded to use those components as inputs and outputs.

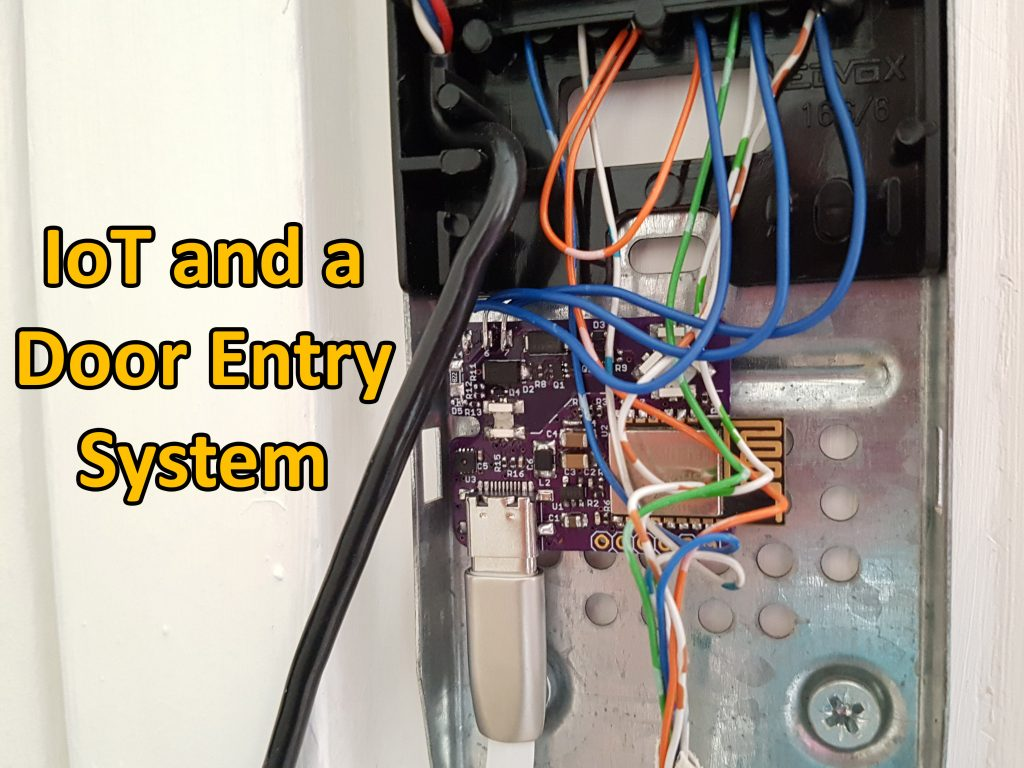

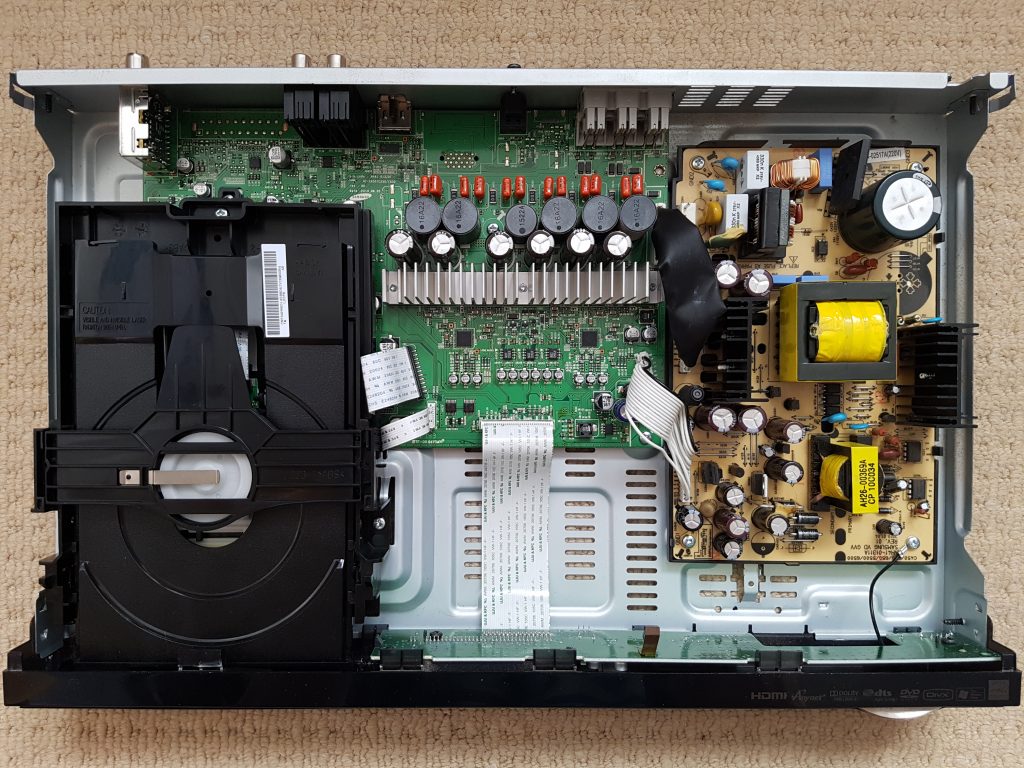

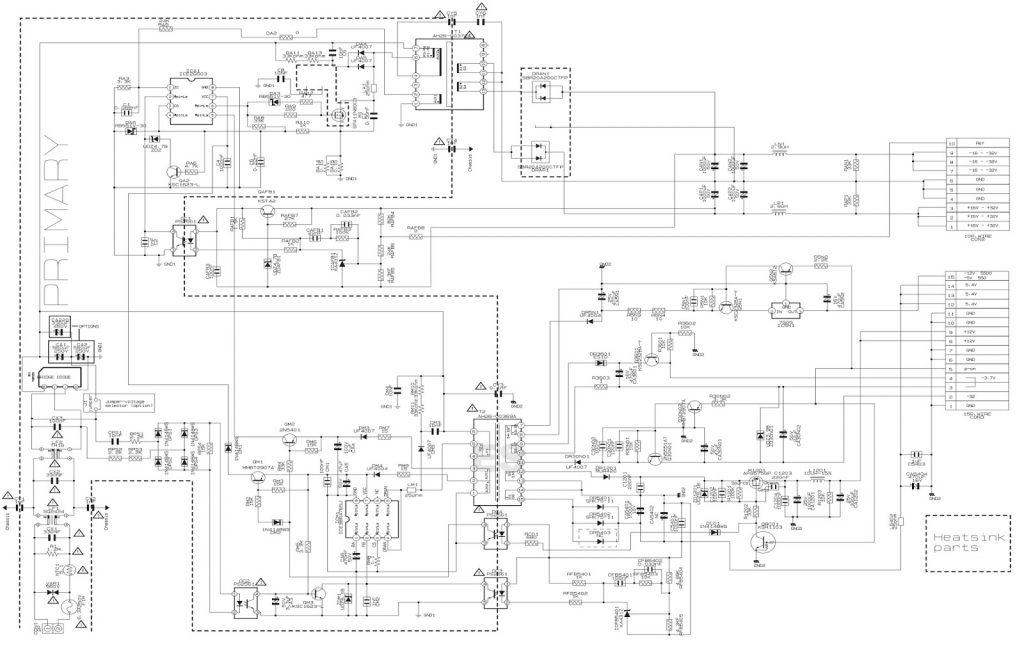

In Homemade Hardware, we make our own circuit boards, so it would be helpful to go through the Arduino Uno to understand all its inner workings and design decisions.

The Arduino Uno is probably the most popular microcontroller among makers and students, since its release in 2010. This is still the case today, because of it’s giant body of open source software, and ease of use.

This popularity is centralized around…